CZT (Cadmium Zinc Telluride, CdZnTe) bare die technology has found widespread use in X-ray detection applications, offering significant advantages over traditional materials. CZT-based detectors are particularly prized for their high sensitivity, excellent energy resolution, and room-temperature operation, making them ideal for various X-ray imaging and spectroscopy systems. These properties make CZT bare dies an attractive choice for use in medical imaging, industrial inspection, security scanning, and other X-ray-based applications where high accuracy and precision are essential.

## Specification

| Parameter Attribute | Parameter Value |

|---|

| Application | X ray |

| Material | Cd₀.₉₀Zn₀.₁₀Te |

| Conduction Type | P-Type |

| Wafer Diameter (±0.1mm) | Customizable Dimensions |

| Wafer Thickness (±0.05mm) | 1/2/5/Custom-made |

| Crystal Orientation | [111] or other crystal orientations |

| Full Width Half Maxium (FWHM) | ≤30 rad·s |

| Zn Composition (x in Cd₁₋ₓZnₓTe) | 0.10±0.04 |

| Precipitate Density (Particle Size Distribution) | 5~10μm ≤1.0×10³cm², 1~5μm ≤5×10³cm² |

| Etch Pit Density (EPD) | ≤5×10⁴/cm² |

| Resistivity (ρ) | ≥6×10¹⁰Ω·cm |

| IR Transmittance | ≥60% (wavelength range: 1.5 μm to 25 μm) |

| Surface Roughness (Ra) | Double-side polishing, Ra≤5nm |

| Total Thickness Variation (TTV) | ≤15μm |

| Leakage Current (ILEAK) | ≤1nA/mm² (@-600V Bias voltage, room temperature) |

| Electron Mobility-Lifetime Product (μτₑ) | ≥10⁻³ cm²/V |

| Hole Mobility-Lifetime Product (μτₕ) | ≥10⁻⁵ cm²/V |

| Maximum Photocurrent (Unpolarized) | 1000nA (60-second X-ray exposure, 120KV) |

| X-ray Response Linearity | ≥99% |

| X-ray Response Uniformity | ≤10% |

| Energy Resolution | ≤6% (Am241@59.5KeV) |

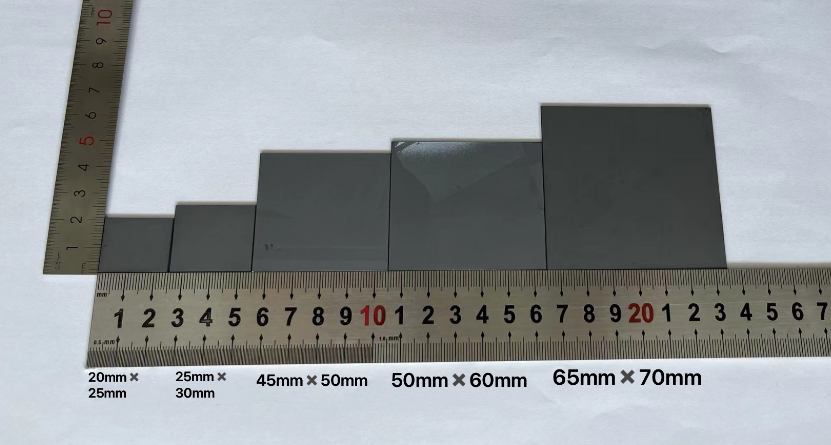

| Dimensions | Custom-made |

| Working Temperature | Room temperature |

## Material Composition and Properties

CZT is a compound semiconductor composed of cadmium (Cd), zinc (Zn), and tellurium (Te). The material's properties can be adjusted by varying the proportion of cadmium to zinc, which in turn influences the bandgap, crystal lattice, and other key characteristics. The bandgap of CZT typically falls between 1.5 eV and 2.5 eV, which is ideal for X-ray detection. This wide bandgap allows CZT to absorb and convert X-ray photons into measurable electrical signals efficiently.

The material’s high atomic number (Z) contributes to its effective interaction with X-ray photons. The higher the atomic number, the more likely an X-ray photon is to interact with the material, leading to the creation of electron-hole pairs that can be detected as electrical signals. This is one of the reasons why CZT is so effective in X-ray detection, as it maximizes the material's sensitivity to high-energy radiation.

## X-ray Detection Mechanism

When X-rays strike a CZT detector, the high-energy photons are absorbed by the material, causing the generation of electron-hole pairs through a process called the photoelectric effect. These charge carriers (electrons and holes) are then collected and measured by electrodes attached to the surface of the crystal. The number of charge carriers generated is proportional to the energy of the incident X-ray photon, enabling the detector to measure the energy of the X-ray with high precision.

Unlike traditional scintillator-based X-ray detectors, which require additional electronics to convert light into an electrical signal, CZT detectors directly convert X-ray energy into charge carriers. This direct conversion mechanism eliminates the need for intermediate steps, resulting in a faster response time and improved energy resolution. The high efficiency of this process enables CZT detectors to provide accurate measurements of X-ray photons, even at lower radiation doses.

## Advantages of CZT for X-ray Detection

1.

High Energy Resolution: One of the most significant advantages of CZT detectors is their exceptional energy resolution. Energy resolution refers to the ability of a detector to distinguish between X-rays of different energies. CZT offers excellent energy resolution, which is crucial for applications like X-ray spectroscopy, where precise measurement of the energy of each X-ray photon is required to identify the material being analyzed. This feature is particularly important in medical imaging, where distinguishing between tissues of different densities and compositions is essential for accurate diagnoses.

2.

Room Temperature Operation: Traditional X-ray detectors, such as those based on germanium (Ge) or scintillators, often require cooling systems to maintain their performance, which increases complexity and operational costs. In contrast, CZT detectors can operate at room temperature, eliminating the need for costly and bulky cooling systems. This characteristic makes CZT-based detectors more cost-effective and easier to integrate into portable or mobile X-ray devices, such as handheld X-ray imaging systems or systems used in field inspections.

3.

High Detection Efficiency: CZT's high atomic number enhances its ability to interact with X-rays, increasing the detection efficiency. The material’s large effective Z-value allows it to efficiently capture a significant portion of incoming X-ray photons. This results in higher detection sensitivity, allowing for more accurate measurements and better image quality in X-ray imaging systems. High detection efficiency is particularly beneficial in low-dose X-ray applications, where maximizing the amount of information captured while minimizing radiation exposure is critical.

4.

Compact and Lightweight: The ability to create compact and lightweight CZT detectors is another advantage in X-ray detection applications. The small form factor makes CZT detectors well-suited for integration into portable devices and systems, allowing for greater mobility and flexibility in a range of environments. This is particularly useful in applications such as security scanning, where compact X-ray imaging systems need to be deployed in various settings.

5.

Direct Conversion of X-rays: As a direct conversion material, CZT converts X-ray photons into charge carriers without the need for a scintillator. This direct conversion process not only improves the speed of the detection but also minimizes losses that can occur in scintillator-based systems. Furthermore, direct conversion allows for the precise measurement of the energy of each incoming X-ray photon, which is essential for applications that require high resolution and sensitivity, such as X-ray spectroscopy and imaging.

6.

Scalability and Flexibility: CZT detectors can be manufactured in various sizes and configurations, making them highly adaptable for different X-ray applications. Whether used in large area detectors for industrial imaging or small, portable systems for medical diagnostics, CZT’s scalability allows for customization to meet the specific needs of the application. The ability to design CZT detectors with tailored properties, such as varying thickness and crystal orientation, further enhances the flexibility of this material.

## Applications of CZT in X-ray Detection

## Medical Imaging

One of the most significant applications of CZT bare die technology is in medical X-ray imaging. CZT detectors are used in digital radiography and computed tomography (CT) systems, where their high energy resolution, high sensitivity, and room-temperature operation provide clear and detailed images with minimal radiation exposure to patients. The direct conversion of X-rays into electrical signals enhances image quality by reducing the blurring and noise that can affect traditional scintillator-based detectors.

In particular, CZT-based detectors are highly effective in applications such as mammography, where precise imaging of soft tissues is critical. The high energy resolution allows for better differentiation of tissues, leading to more accurate diagnoses. Additionally, the ability to operate at room temperature eliminates the need for cryogenic cooling, simplifying the design and reducing operating costs for medical imaging systems.

## Industrial and Security Inspection

In industrial applications, CZT detectors are used for non-destructive testing (NDT) and inspection of materials. X-ray imaging is commonly employed to detect defects in metals, composites, and other materials used in manufacturing. The high sensitivity and energy resolution of CZT detectors allow for detailed imaging of internal structures, making it easier to identify cracks, voids, and other irregularities in the material. Furthermore, CZT-based X-ray detectors can be integrated into automated systems for real-time inspection during manufacturing processes.

Security screening systems, such as those used in airports or public buildings, also benefit from CZT-based X-ray detectors. The ability to capture high-resolution X-ray images quickly and accurately helps security personnel identify hidden objects, such as weapons or contraband, in luggage or cargo. CZT detectors offer the advantage of high detection efficiency, which is essential in ensuring fast and reliable screening in high-throughput environments.

## X-ray Spectroscopy

CZT is also widely used in X-ray spectroscopy, where it serves as a detector for identifying the elemental composition of materials. By measuring the energy of X-ray photons that interact with a sample, CZT detectors can provide valuable information about the material’s composition, allowing for precise chemical analysis. This is particularly useful in applications like geological exploration, materials science, and nuclear physics, where understanding the elemental makeup of samples is critical.

In X-ray fluorescence (XRF) analysis, CZT detectors offer high resolution and sensitivity, allowing for accurate identification of trace elements and isotopes in a sample. The ability to measure the energy of X-ray photons precisely enhances the accuracy of X-ray spectroscopy, making CZT an essential tool in analytical laboratories and research environments.

## Challenges and Future Developments

Despite its many advantages, there are some challenges associated with CZT-based X-ray detectors. One of the primary challenges is the growth of high-quality CZT crystals. Defects and impurities in the crystal structure can lead to reduced performance, particularly in terms of energy resolution. However, advancements in crystal growth techniques are expected to improve the quality of CZT materials and reduce these issues.

Additionally, while CZT detectors offer high performance at room temperature, they can still be more expensive to produce than traditional scintillator-based detectors. Ongoing research and development in manufacturing processes are focused on reducing the cost of CZT production, making it more accessible for a wider range of applications.

## Conclusion

CZT bare die technology has established itself as a key material for X-ray detection due to its exceptional energy resolution, high detection efficiency, and room-temperature operation. These advantages make CZT-based detectors ideal for use in a variety of X-ray applications, including medical imaging, industrial inspection, security screening, and X-ray spectroscopy. With continued advancements in crystal growth and manufacturing processes, CZT detectors are expected to play an increasingly important role in the future of X-ray technology, offering more accurate, cost-effective, and versatile solutions for detecting and analyzing X-ray radiation.

CdZnTe Association (CdZnTe.com)

https://www.cdznte.com/detector/czt-detector-bare-die-for-x-ray.html