The primary limitation of

Cadmium Zinc Telluride (CZT) detectors lies in their

material growth challenges and

cost-effectiveness, particularly related to achieving high-quality crystals suitable for radiation detection. While CZT detectors offer significant advantages in terms of

energy resolution,

direct charge conversion, and

room temperature operation, several key factors limit their widespread application and overall performance.

Here’s a detailed explanation of the primary limitation of CZT detectors:

## 1. Challenges in Crystal Growth and Material Quality

The most significant limitation of CZT detectors is the

difficulty and

cost involved in growing high-quality CZT crystals. Unlike more widely used materials like

silicon or

germanium, CZT crystals are

harder to grow with consistently high

quality. Several issues contribute to this challenge:

*

Crystallization and Defects: Producing large, high-quality CZT crystals with a

low defect density is a complex and energy-intensive process. Crystallization defects, such as

grain boundaries,

dislocations, and

impurities, can dramatically affect the

charge transport properties of the material, leading to poor performance in terms of

energy resolution and

sensitivity. Defects in the crystal structure can increase

leakage currents and

reduce charge collection efficiency, both of which degrade the detector’s overall performance.

*

Doping Issues: Achieving the right

dopant concentration for CZT is another challenge. The material needs to be

dopant-engineered to optimize its

charge transport properties, but maintaining uniform doping and preventing

non-stoichiometric compositions during growth are challenging tasks. Inconsistent doping can affect the

response time,

charge collection efficiency, and

energy resolution of the detector.

*

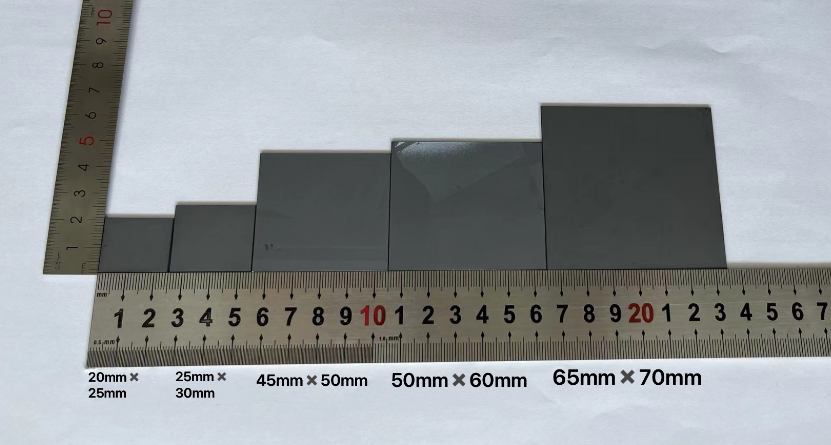

Size of Single Crystals: The size of the CZT crystals directly affects the size and performance of the detectors. Growing large

single crystals of CZT with uniform properties across the entire crystal volume is a significant challenge. Larger crystals are typically more difficult and expensive to produce, and they may exhibit

non-uniformities that hinder the detector's ability to collect charge uniformly, further reducing its performance.

*

Cost of High-Quality Material: Due to the difficulties associated with crystal growth and material processing, the cost of high-quality CZT material is much higher compared to other semiconductor materials like

silicon. The

high cost of CZT crystals remains a limiting factor in the widespread adoption of CZT detectors, particularly in commercial and industrial applications.

## 2. Material Sensitivity to Radiation Damage

Another limitation of CZT detectors is their sensitivity to

radiation damage, which can occur during prolonged exposure to high levels of ionizing radiation, especially at high energies. Radiation-induced damage can lead to

defect formation within the crystal structure, negatively impacting the performance of the detector.

*

Ionizing Radiation Damage: Exposure to ionizing radiation can cause changes in the

crystal lattice, introducing

traps for charge carriers, which can increase

recombination rates and reduce

charge collection efficiency. This radiation damage can accumulate over time, affecting the

long-term stability of CZT detectors, particularly in applications involving

high radiation doses or

intense radiation fields (e.g., in

nuclear reactors or

space applications).

*

Reduced Sensitivity and Resolution: As the material undergoes radiation damage, the

energy resolution and

sensitivity of the detector degrade, and the

spectral performance becomes less reliable. This is particularly problematic in applications like

nuclear spectroscopy or

gamma-ray imaging, where high

energy resolution is critical for accurate measurements.

## 3. Temperature Sensitivity and Cooling Requirements

Although CZT detectors are prized for their ability to operate at

room temperature (a distinct advantage over other semiconductor materials like

germanium, which requires cryogenic cooling), they are still susceptible to temperature effects, which can limit their performance under certain conditions.

*

Temperature Dependence: As the operating temperature of CZT detectors increases, the

leakage current rises, and the

charge collection efficiency decreases. The temperature sensitivity of CZT detectors can lead to

decreased energy resolution, especially at temperatures above

50°C. For high-precision applications, such as in

medical imaging or

nuclear spectroscopy, maintaining

temperature stability is critical, and external

cooling mechanisms (such as

thermoelectric coolers) may be required to prevent performance degradation at elevated temperatures.

*

Need for Cooling in High-Temperature Environments: While CZT detectors do not require

cryogenic cooling like

germanium detectors,

active cooling systems are often still necessary to ensure optimal performance in high-temperature environments. This increases the complexity, weight, and power consumption of the system, particularly in mobile or portable radiation detection applications, which is an important factor in their use in areas like

space exploration or

field radiation monitoring.

## 4. Manufacturing and Production Scale Challenges

Manufacturing CZT detectors with

uniform performance across multiple devices is another limitation. The production of CZT crystals is not yet fully

scalable to meet the demands of large-scale applications, and the process of

quality control can be difficult to standardize across batches.

*

Inconsistent Performance: Even small variations in crystal quality or doping levels can lead to

significant variations in the performance of individual detectors. This inconsistency makes mass production of CZT-based detectors challenging and contributes to the

high cost and

longer production timelines.

*

Economic Constraints: The complexity and expense of manufacturing high-quality CZT crystals limit the affordability and accessibility of CZT detectors, making them less attractive for widespread adoption in commercial systems compared to other radiation detection technologies such as

scintillation detectors or

silicon-based detectors.

## 5. Material Purity and Impurity Contamination

CZT detectors require

high purity in the starting materials, including

cadmium,

zinc, and

tellurium. Impurities or contamination during the crystal growth process can introduce defects and affect the detector's performance.

*

Impurity Effects: Even small amounts of impurities in the CZT material can create

trap sites for charge carriers or alter the material’s

electrical properties, leading to reduced

charge collection efficiency and

energy resolution. The purity of the raw materials and the

controlled environment required for crystal growth make the process

costly and

sensitive to external factors.

*

Contamination Risk: Maintaining an

ultra-clean environment during the growth of CZT crystals is crucial to prevent contamination, which adds complexity and cost to the manufacturing process.

## Conclusion

The primary limitation of

CZT detectors is the

difficulty in producing high-quality crystals with low defect densities and the

high cost associated with crystal growth and material purity. These factors contribute to challenges in

scalability,

consistency, and

affordability, limiting their widespread application compared to other semiconductor materials. Additionally, the

sensitivity to temperature changes, the potential for

radiation-induced damage, and the requirement for

cooling systems in certain applications further constrain the operational range of CZT detectors. While they offer excellent

energy resolution and the ability to operate at room temperature, these limitations must be carefully managed for the successful implementation of CZT-based radiation detection systems.

CdZnTe Association (CdZnTe.com)

https://www.cdznte.com/blog/what-is-the-primary-limitation-of-czt-detectors.html